Open Innovation

Further development of our products together with suppliers and colleges, in close collaboration with our customers

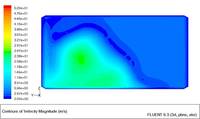

With duct burners in particular, the flow conditions before the burner are important for the most even temperature distribution possible after the burner and for low flue gas levels.

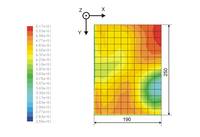

The structural design of centrifugal fans that are commercially available leads to inhomogeneous speed distribution on the blower’s outlet connection (Fig. 1).

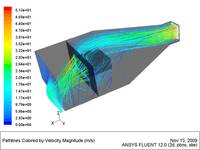

The relatively large angle of opening of the transition piece also leads to separation phenomena (Fig. 2).